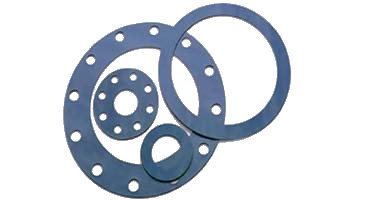

Talbros cuts Non-Asbestos Gaskets from material sourced from various manufacturers and can supply this material co-branded or private branded.

In our bid to become a diversified sealing material supplier, this division is our most recent diversification. Talbros cuts Non-Asbestos Gaskets from material sourced from various manufacturers and can supply this material co-branded or private branded.

Most of todays non-asbestos gasket materials contain either Kevlar, an aramid fiber, fiberglass, carbon, graphite or another mineral fiber. Regardless of the manufacturer, the basics are the filler and the elastomer used. While no two compounds (or the % of filler) are identical, the basic Elastomers are: NBR (Buna-N), SBR, EPDM or Neoprene. If you examine which material you need (as defined by the application) and select the non-asbestos gasket material with that elastomer you will usually do well. This method will also allow you to select a competitive brand that will serve your application. No two materials are identical so caution must always be exercised.

In general the common “Binders” are:

NBR – good for oils, gas, mild chemicals and water

SBR – good for saturated Steam, mild chemicals inert gas and water

Neoprene – good for saturated steam, refrigerants, oils, fuels, mild acids and alkalies and water.

EPDM – good for saturated steam, mild chemicals and water

Each material listed will indicate the “Binder” which makes cross referencing equal materials a much easier task. You should however pay attention to Tensile strength (for pressure resistance) Temperature ratings, and Compression / Recovery ratings.

You must also consider for cut gaskets Size, Temperature, Application, Media, Pressure, Speed (if dynamic) of your specific application. If this is for a finished gasket you will also want to consider bolt loads, the size of bolts, the number of bolts, the bolt material and the available torque.